Stamping Capabilities

Our core competency is metal stamping with over 82 years of experience that is at service to our customers. Our investment in our people and process are the critical enablers to quality part service. While we are capable of a wide variety of manufacturing, it is our specialization in part sub-categories that make us most valuable to our customers.

We work with steel, stainless steel, aluminum and copper materials and have specialized experience manufacturing parts in the following industries:

Automotive, Appliance, Construction, Office, Medical, Government/Military

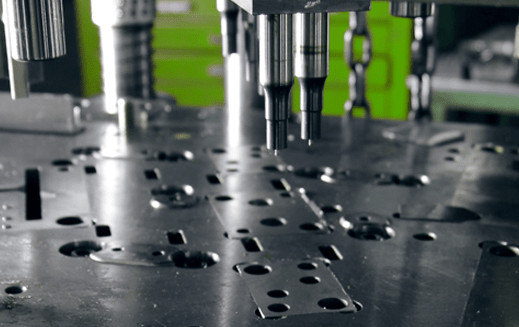

We operate presses ranging from 80 to 1,000 tons – including straight sided presses and high speed Minsters – and process small component stamping at speeds up to 200 SPM. Specialized stamping capabilities include:

Progressive, Transfer, In – die welding, In – die stud insertion,

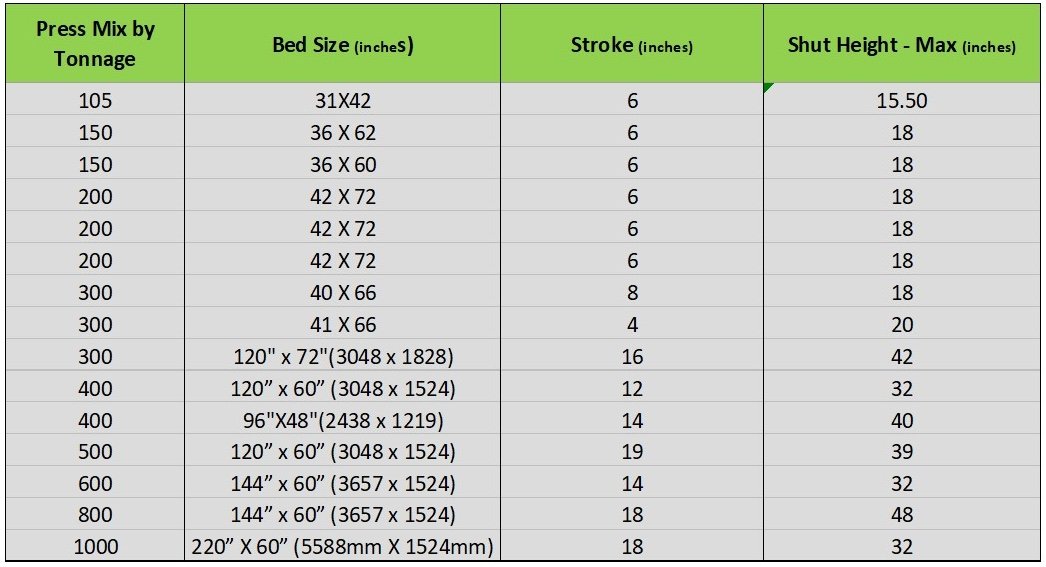

Press Mix Overview - Markham

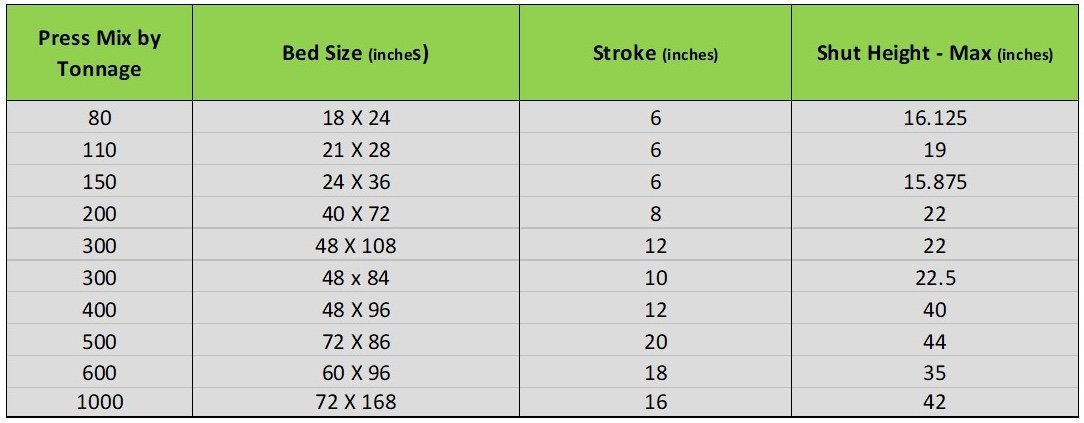

Press Mix Overview - Middleville

Our latest Press addition:

VERSON 1000 ton with Linear servo transfer

- Transfer stamping – 1,000 ton

- In-die welding – 1,000 ton

- In-die insertion of stud or nut

- Dual or tri-layer stampings for heat shields and sound deadening stamping’s

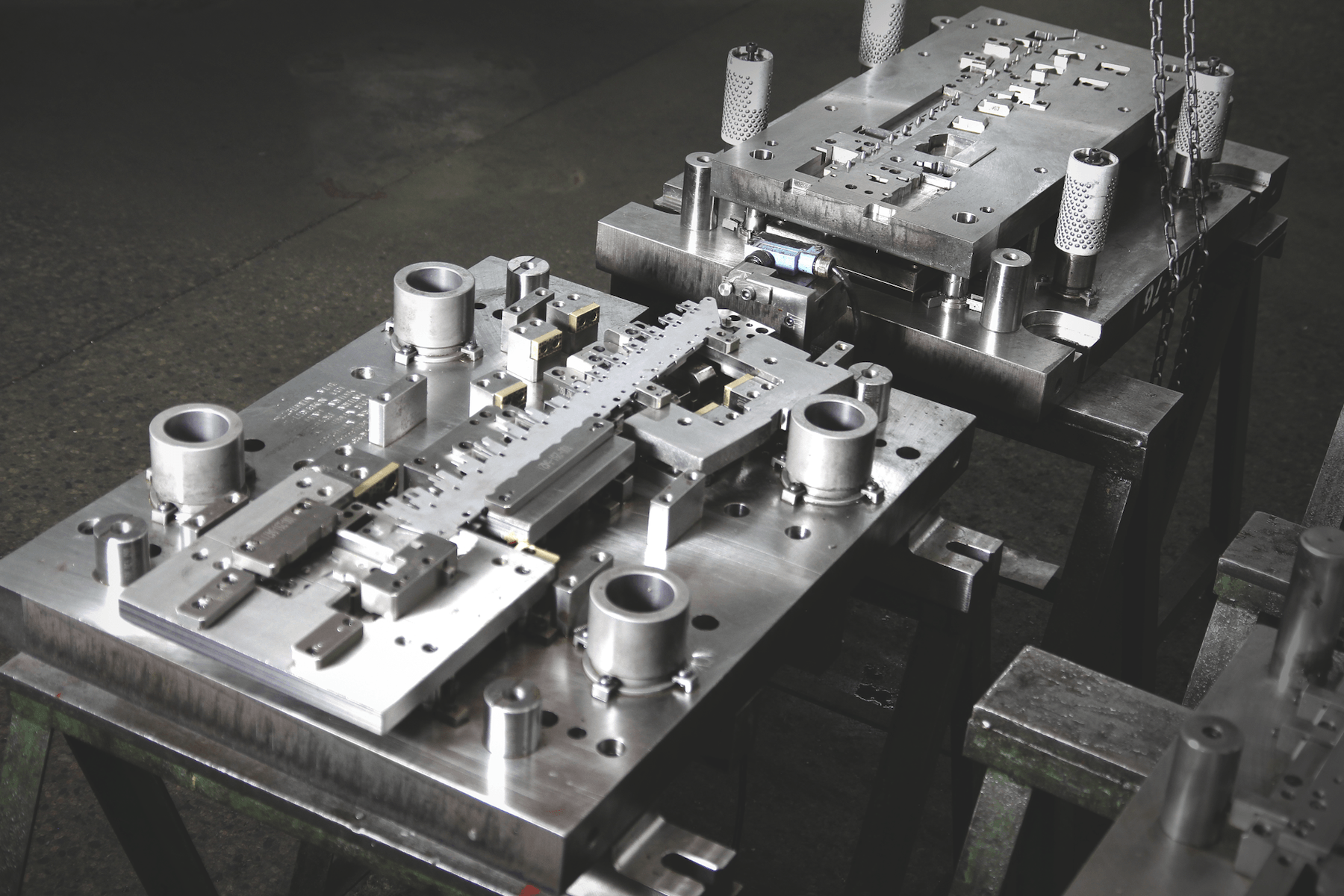

Tool and Die Design & Build

Our manufacturing expertise starts in our tool room where our experienced tool makers design and build a wide range of dies, from sophisticated progressive dies to simple and cost-effective hand transfer dies. In conjunction with our tools, we build assembly fixtures, machining fixtures, and also operate an extensive fabrication department to suit your needs.

Our tool makers also build and service injection molds, inspection gauges and welding fixtures. We source high-quality tool steels for our dies and tooling, including A-2, D-2, M-2, and 4140 steel. Our precision machinery holds tolerances as close as ± .002″.

Sub-Assembly Operations

In support of our stamping and molding services, we also deliver a full complement of mechanical assembly services for secondary operations, including:

- Adhesive Application

- Orbital Riveting

- Tapping

- Welding

- Stud/Nut Insertion

Our specialists operate air tools, hand tools and welders, in addition to custom assembly fixtures, to meet all project requirements and specifications. We are pleased to offer rush production services and can handle mid- to high-volume orders. Quality assurances include ± .005″ tolerances and ISO 9001:2008 certification.

Product Engineering

From designing new dies to troubleshooting and problem-solving existing dies and molds, we provide our customers with an unsurpassed level of quality craftsmanship, build management and value.